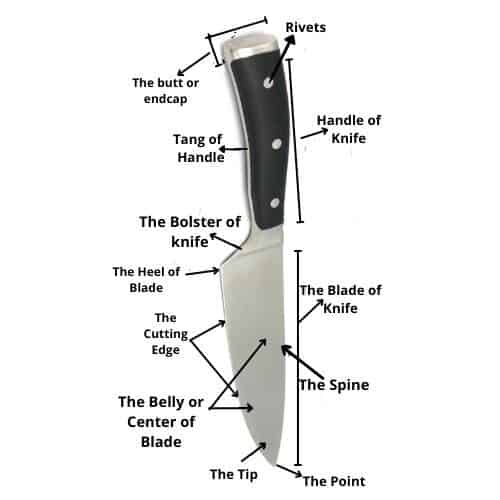

Although everyone can recognize a kitchen knife, not all of us can define the main kitchen knife parts or comprehend the terms used to describe the structure of a knife.

Knowing and understanding the terms used to describe the components of a knife will help you make the best decision when purchasing a knife for your kitchen.

Here, we will look at the components of a chef’s knife or any type of knife. in fact, these components are what determine the knife’s quality.

So, we will basically divide the knife into two separate parts: the blade and the handle.

The Parts of the Kitchen Knife’s Blade

The central body of the kitchen knife is the blade, which contains the point, tip, blade edge, spine, and heel.

The blade’s size, form, and material are the knife’s defining qualities.

Blade Material

Since the material selected to manufacture your kitchen knives significantly influences their strength, longevity, and sharpness. So, learning more about the best knife blade materials before purchasing can be helpful.

It is worth mentioning that each material has advantages and disadvantages. And certain materials are well designed for certain jobs than others.

Stainless Steel Blades

The first thing to know is that stainless steel is the most common knife material. Due to its high durability and resistance to rust and corrosion.

Because stainless steel is manufactured from a carbon and iron base, chromium is added to resist discoloration. And give the blade a long-lasting shine. This makes the knife edge robust, long-lasting, and stain-resistant.

The disadvantage of stainless steel is that there are already a broad number of commercially useable alloys. Therefore, the quality of the steel may vary greatly depending on the manufacturer.

Although these blades are popular due to their rust resistance. They may discolor in some conditions and are not as sharp as carbon or ceramic knives.

Kitchen cutlery, diving knives, and pocket knives are all examples of knives with stainless steel blades.

Carbon Steel Blades

Carbon steel is a kind of steel alloy composed of carbon and iron. that lacks the chromium used in stainless steel to help them resist stains.

High-carbon steel is frequently used to forge blades that require remarkable strength and toughness. And it may also maintain an incredibly sharp edge if cared for properly. As a result, carbon steel is an excellent choice for peeling knives and cleavers.

Carbon steel blades, on the other hand, are prone to staining and discoloration. Especially when they come into contact with acidic foods.

Therefore, high-quality kitchen knives are hardly manufactured from it.

So, if you are looking for a long-lasting, sparkling collection of knife set to show off. It may not be the best option. If the sharpness and longevity of the edge are your only concerns. You will not find a sharper knife than one made of carbon steel.

You can also read our forged knife VS stamped knife comparison

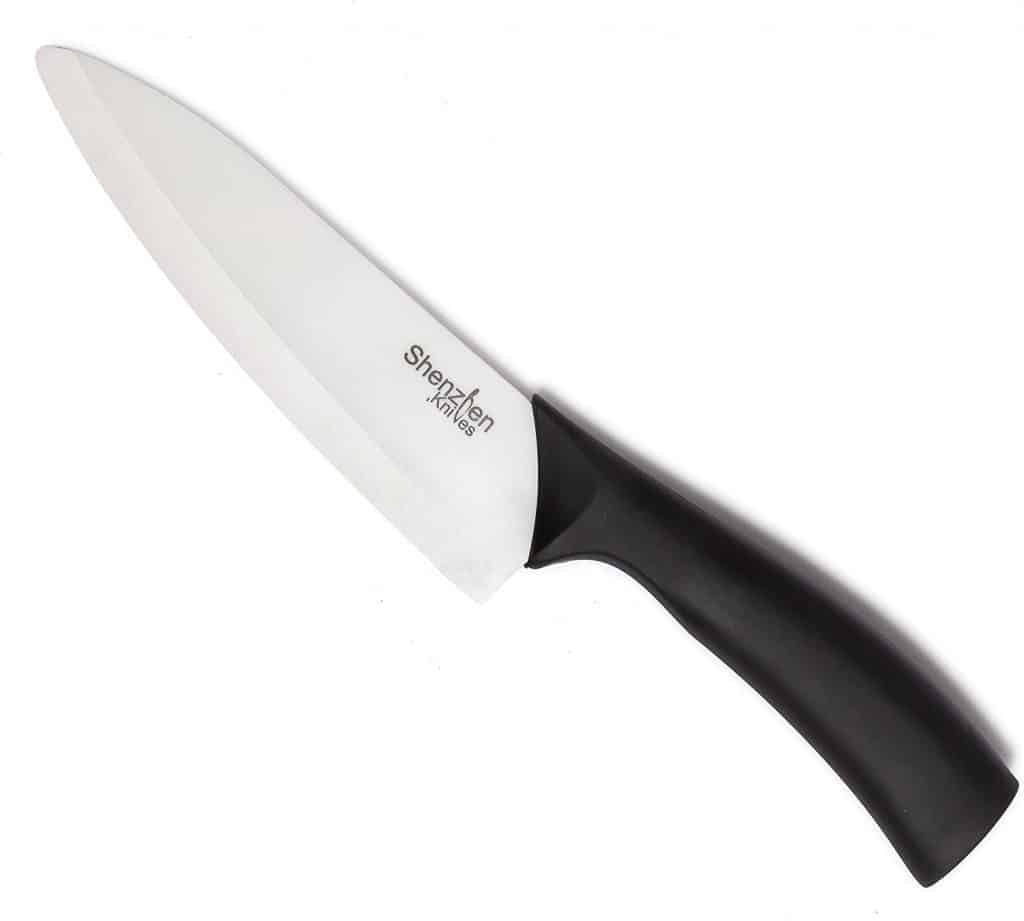

Ceramic Blades

A ceramic blade is made of hardened zirconium dioxide. They are non-metallic and non-magnetic. And they are frequently coated with other materials to make them more durable.

It is worth mentioning that they are relatively lightweight, which many cooks like. And they are also considered to be extra hygienic than metal types.

Another advantage of a ceramic knife is that it may be printed with fashionable patterns, colors. Or details, making them even more appealing to have on display.

The main disadvantage of a ceramic knife is its fragility. Since they are more prone to breakage or cracking if dropped than other kinds of blades. Therefore, they must be handled with care.

Regular whetstones may harm the blades. Therefore, they must be sharpened using a specialized knife sharpener. However, with careful care, a ceramic knife should remain a useful cutting tool for many years to come.

Damascus Steel Blades

Damascus steel is created by hammering two or more different metals together. Which will create strong steel with an elegant, wavy pattern.

This kind of metal is powerful, robust, and sharp. But it is now mostly regarded for its aesthetically appealing form.

Titanium Blades

Titanium is non-magnetic and rust-resistant. Which makes it an excellent material for pocket knives and dive knives.

But it is less useful as a culinary knife than steel or ceramic. Since it is less sharp and does not maintain an edge as well.

Also read , How to Hone Your Knife? | Easy Guide

The Edge of the Blade

Whether you are utilizing a chef’s knife, paring knife, boning knife, or any other type of knife. The edge is the long, sharp section of the blade that does the majority of the cutting.

Slice, dice, mince, chop or perform just about any other basic kitchen cutting task using the cutting edge.

It is worth mentioning that its beveling classifies the sharpness of a kitchen knife blade. That represents the angle at which the edge is grinding down to the sharp edge.

To make things more straightforward, The sharper the blade, the lower the bevel angle.

The majority of western kitchen knives are double-beveled. Which means they are sharpened on both sides. However, a Japanese kitchen knife, such as the santoku, has just one beveled side.

The blade’s “grind” refers to how this cutting edge is constructed. And various grids are used for multiple things.

What are the different grinds of the kitchen knife blade’s edge?

Hollow Ground Edge Grind

The cutting edge of the hollow-ground edge is fine and ultra-sharp. They are perfect for making a clean, smooth cut and are often seen on filleting knives and chef’s knives.

The drawback of a hollow ground edge is that it is relatively fragile. And will chip if used for difficult cutting.

Read more , How to shuck oysters without an oyster knife

Flat Edge Grid

Flat-ground knives have a weaker sharpness but are more durable than hollow-ground blades. Meat Cleavers’ blades are typically flat ground. Which allows them to cut across cartilage and bone with ease.

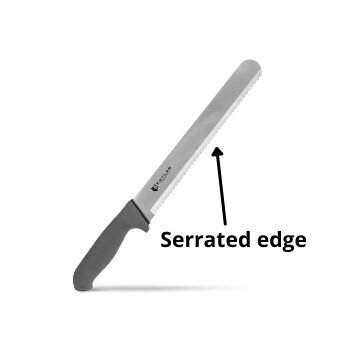

Serrated Edge Grid

Serrated blades are meant to cut through hard components. Because the blade’s teeth offer extra cutting strength. Such as a bread knife and steak knife.

What are the different types of the blade’s knife edge?

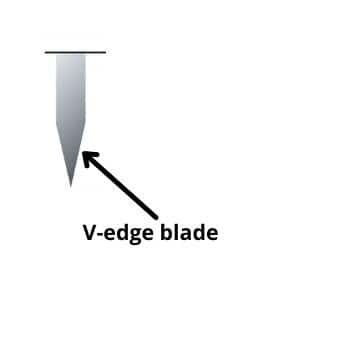

V-edge Blade

This is the most popular kitchen knife-edge type. The ‘V’ refers to the blade’s cross-section design, which is flat on both sides and shrinks to a point.

It is worth mentioning that this type of edge is pretty straightforward to have while sharpening a knife or honing it with a honing steel. And it lasts longer than other thinner edge types.

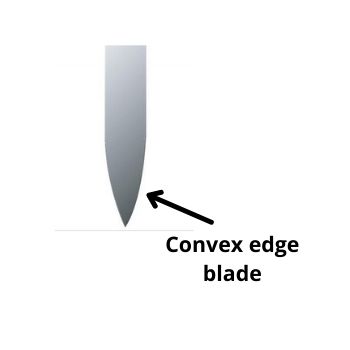

Convex Edge Blade

The edges are curved as they reach the point, making it similar to the V-edge. It has a bullet-like structure in cross-section.

Noting that, it is more durable than the V-edge, yet it still has a razor-sharp edge. Yet, Multiple sharpening will eventually turn this edge into a typical V edge type.

Read more , How to Care for Your Paring Knife?

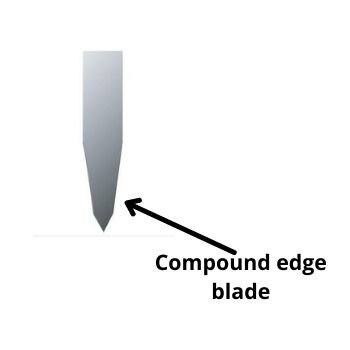

Compound Edge Blade

This kind of edge has a sharper angle at the blade’s tip.

It is worth mentioning that this style of edge prevents the edge from ‘rolling’ or breaking. Thus, it is effectively preserving sharpness and longevity.

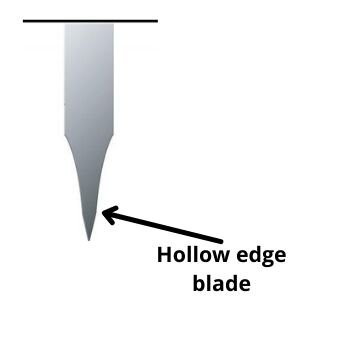

Hollow edge blade

This edge is the total opposite of the convex edge, with the sides hollowed down slightly.

Because its thinness results in a very sharp kitchen knife blade, but it is also more vulnerable to damage. Knives for hunting and outdoor activities are often designed with this blade.

This is the Japanese type of blade, which has an angle on one side and is flat on the other, like a chisel.

Noting that, it is mostly found in sushi and sashimi knives, including the Santoku knife and Nakiri knife.

Keep in mind that chisel edge knives are the only kind that matters if you are left or right-handed. So, ensure you get the suitable one.

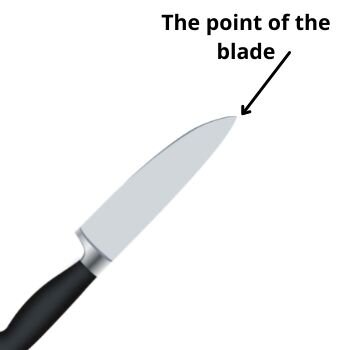

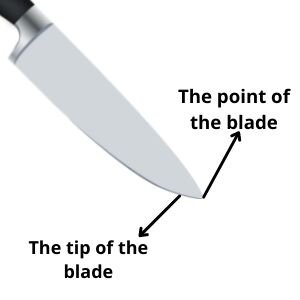

The Point of the Blade

A kitchen knife’s point is the section where the spine and the edge meet at the front area of the blade. It is useful for piercing, beginning a tough cut, and even keeping your meat in place as you slice using another sharp knife.

Keep in mind that not all blades have points. For example, a specialty slicing knife or bread knife and the ordinary dining knives have a curved end.

It is mainly used for penetrating and marking. And it is a crucial component of a paring or boning knife. Noting that, During mincing, the tip of a chef’s knife or santoku knife functions as a guideline.

The point of a knife may curve upwards, defined as a ‘trailing point,’ as with a fillet or boning knife, and sometimes downwards.

But you will not often get this ‘hawkbill’ form in the ordinary kitchen. Some cheese knives feature a dual point and might very well use it as a fork.

There are various types of points, each with its own structure. We will discuss them in detail down below.

What are the different shapes of a kitchen knife blade’s point?

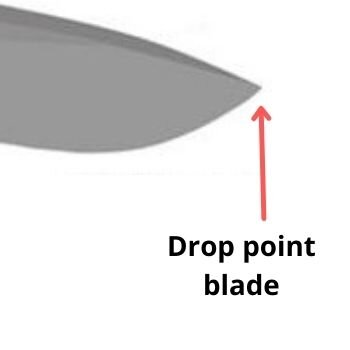

Drop Point Blade

The drop-point is one of the most popular kitchen knife blade forms. With a curved spine that folds down from the handle to the tip.

This results in a tip that is easier to control and a larger belly for slicing. Drop points are ideal for hunters and can sometimes be useful for a different purpose.

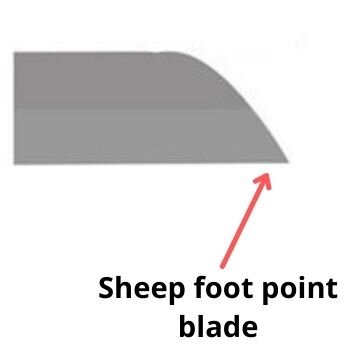

Sheep Foot Point Blade

The main thing about the point is that the blade design is with a straight edge. And a spine that curves down to join it at the tip.

Sheepsfoot blades are built for slicing while reducing the chance of undesired puncture with the tip. It was utilized to cut sheep hooves, but it is now employed as a survival tool.

Check also, Best Bread Knife

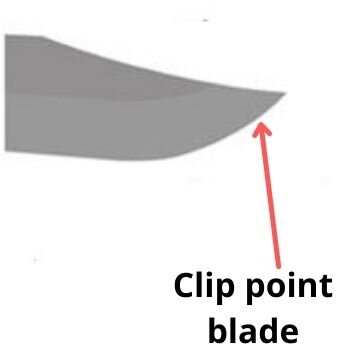

Clip Point Blade

The clip point is a popular blade form with a spine that seems to be cut off at the front.

Noting that, this cut-out part may be straight or curved. And it creates a sharp point that is suitable for accurate and consistent work.

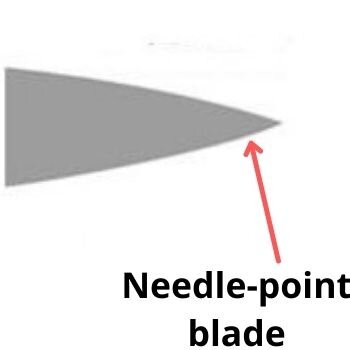

Needle-point Blade

The needle-point is a uniform blade with two sharply tapering edges from handle to tip. It is worth noting that this design enhances the kitchen knife’s piercing and penetration capabilities.

Due to its small design, the needle-point is considerably more fragile than equivalent blades. Particularly spear points.

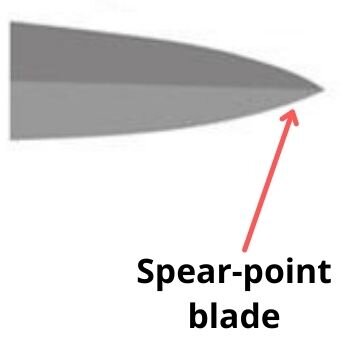

Spear-point Blade

The point of a spear-point blade is aligned to the kitchen knife’s center.

It is worth noting that this design is both more robust and more skilled at stabbing than the comparable needle-point.

A spear point, in addition, may have one or two sharp edges.

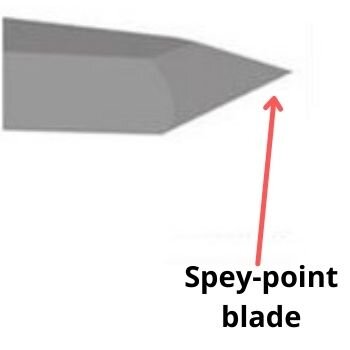

Spey-point Blade

A Spey point blade has a fairly flat edge until it bends up to a point near the tip. The spine, like the edge, is mainly flat but bends down near the tip of the blade to form the point.

It is worth noting that this technique creates a kitchen knife with a small belly and a broad tip, which minimizes unwanted piercing.

These blades were first utilized on farms on animals, but they are now popular on conventional trapper blades. Besides, they are often found in multi-blade designs and are preferred among hunters.

Trailing-point Blade

The spine of a trailing point blade bends upward to form a raised tip that is taller than the handle. This form produces a large belly, making it ideal for slicing, skinning, and a fillet knife.

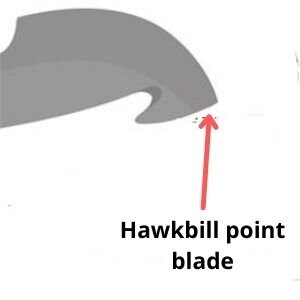

Hawkbill Point Blade

Hawkbill knives, sometimes known as talons, have a spine and edge. These both bend downwards in the same direction to produce a downward-facing point.

The benefit of this design is that it helps the blade to cut appropriately. When the knife is drawn back in the direction of the handle.

Thus, they are mainly used for practical tasks as cutting carpet and tile and trimming plants.

Read also , Things to Consider When Buying an Electric Knife Sharpener

The Tip of the Blade

The tip of the blade is slightly behind the point. It is the kitchen knife blade’s last quarter, and you use it to chop and divide tiny items.

You may also utilize the tip of your blade for more delicate slicing tasks. Such as cutting garlic and onions.

Keep in mind that you may experience bending or even cracking of the tip in low-quality knives. Due to a highly flexible blade.

Noting that flexibility is essential in some types of food preparation. Such as when boning or filleting. By allowing the blade to move around the solid parts. It is better to verify that any flexibility is structured correctly and is not a cheap design.

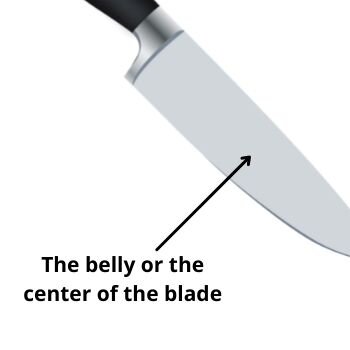

The Belly or the Center of the Kitchen Knife Blade

The belly refers to the segment of the kitchen knife edge closest to the tip of the blade. It is also the section of the knife that undergoes maximum damage. And demands the most sharpening.

Considering it is so far away from the handle, it is best not to put too much pressure.

By using the belly, you can perform Long, slicing motions. Noting that it is often known as the knife’s center. As a result, you can trust it with all your usual chopping and slicing.

At the same time, it is ideal for delicate and precise cuts.

It is worth mentioning that Knives with “curvy” bellies. And tiny points are ideal for chopping or slicing vegetables. Because they permit fast, soft rocking moves on the cutting board.

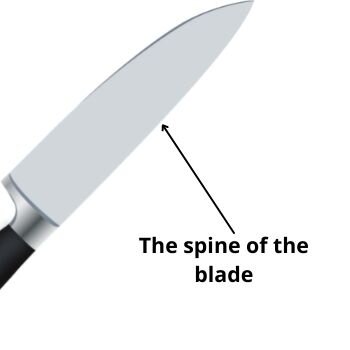

The Spine of the Kitchen Knife Blade

The spine is the kitchen knife blade’s upper, dull side, and it is denser than the bottom half. Thickness varies amongst knives and is a vital factor in the full power and balancing of the blade.

Taking into consideration, the broad top edge of the blade going from the tip to the handle. Or bolster is not a cutting surface.

Because you will often press the palm of your hand on the knife’s spine. So, you can push it downwards while cutting more tough things effectively. The spine must be dull.

Keeping in mind that a knife with a thicker spine may withstand more pressure than one with a thinner spine.

It is worth noting that the spine’s weight influences how carefully you can utilize the knife.

As a result, a knife with a heavy blade is better for strong chopping. While a knife with the weight centered in the handle is better for delicate cutting.

A fillet knife, for example, will have a thin spine and be flexible. But a cleaver would have a robust spine to withstand continuous chopping.

When checking out various knives, make sure the spine has been rounded down. Or they are sanded to remove any sharp edges.

Since a few versions have overlooked this crucial factor. It is resulting in injuries from the supposedly dull edge.

The Heel of the Kitchen Knife Blade

The heel of the kitchen knife is the segment nearest to your hand. This is where the blade stops, and the knife glides upwards into the handle.

Keeping in mind that the lower part of the heel, like the spine, will be unsharpened. Since you do not want to injure your hand on the knife’s edge.

It is worth mentioning that this segment of the blade is designed for cutting through harder components. that need a little more power or strength, such as cutting down the skin of a heavy pumpkin, nuts, or a firm carrot.

Keeping in mind that you may push down on the back of the spine. That is, to supply the heel with additional strength to break through those strong bones.

A sharp and firm heel may be pretty handy, particularly on a boning knife or a chef’s knife. Since you may want it to slice into thick skin or fibrous vegetables at times.

It is worth noting that almost all kitchen knives have a visible heel. They provide sufficient distance between your hand and the blade so you do not hurt yourself.

Other knives, such as steak knives or pocket knives, may or may not have a heel.

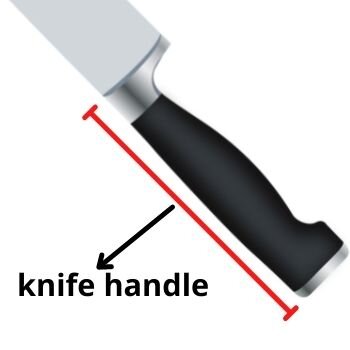

The Parts of the Kitchen Knife Handle

Let us look at the handle now that we have looked at the blade.

You should grip the knife by the handle. It is usually made up of two scales that cover the tang and are riveted for further security.

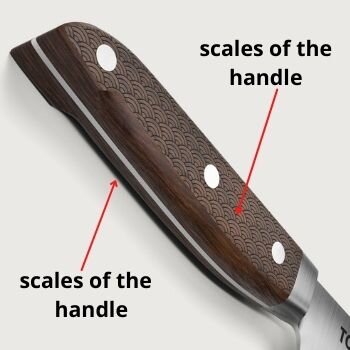

The Scales of the Kitchen Knife Handle

In a kitchen knife, the material that makes up the scales. Also known as the handle, maybe a broad range of materials. However, wood, plastic, and steel are the most popular.

The most crucial aspect of a kitchen knife’s handle is that it is comfy to hold and does not get slippery quickly.

This is particularly true if the knife’s handle is wet. which is common in a kitchen where fruits, vegetables, and utensils are washed often.

What is the best type of materials for the kitchen knife handle?

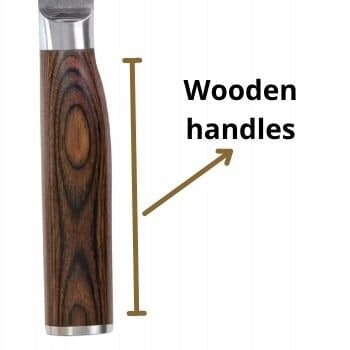

Wooden Handles

One of the first and most genuine types of knife handles is the wooden kitchen knife’s handle.

It may be an expensive or low-cost choice. However, that provides very stylish characteristics thanks to personalized carvings and designs. Those are meant to complement the knife.

Wooden handles may also be manufactured from a variety of various woods. Noting that, Hardwoods are chosen over their softer equivalents. As they are more robust and impact-resistant.

Keep in mind that many less pricey wooden handles knives are constructed from treated wood. Which may look lovely but not last as long.

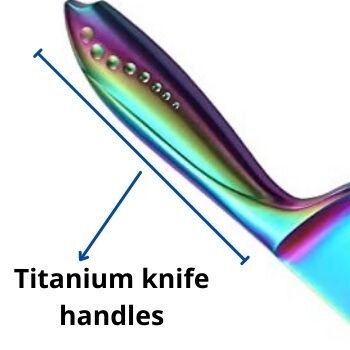

Titanium Knife Handles

Titanium kitchen knife handles are a step up from aluminum handles in terms of strength. But they are also more expensive.

One notable feature about Titanium is that it is sleek, low-density. And high-strength metal alloy.

It is worth mentioning that titanium knife handles are lighter than aluminum. And more scratch and wear-resistant.

Furthermore, this kind of handle has the best degree of rust tolerance for any metal available.

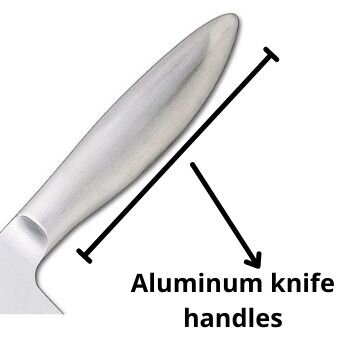

Aluminum Knife Handles

Kitchen knife handles made of aluminum are an affordable choice that comes in a variety of colors. In addition, they have rust and corrosion-resistant features. Which makes them ideal for long-term elegance and performance.

They are non-metallic, lightweight, and maybe colored to enrich the handle’s appearance and style. But The grip is restricted, but the handle’s form and feel improve stability.

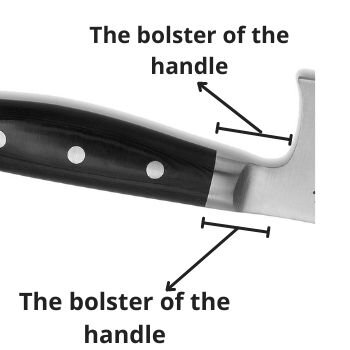

The Bolster of the Kitchen Knife Handle

The first thing you need to know is that the bolster is a strong metal section that links the blade to the handle. Its purpose is to enhance the balance of a kitchen knife.

Mainly The bolster is the finger guard. That prevents your hand from sliding forward and hitting with the edge.

It is worth noting that not only is it safer, but it is also more comfortable. Since you do not have to grasp as tightly or change your grasp as much to prevent from sliding.

A bolster is an important aspect of knives used for cutting raw meat or filleting fish. Because it can be pressed down on for added force. And it keeps the blade from sliding if your hands become slippery.

Often, bolsters are only found in forged knives. a Stamped knife and a Japanese knife do not feature them. One benefit of not having a bolster is that you may sharpen the entire length of the blade.

Keeping in mind, a forged knife is one that was constructed by heating. And shaping metal to the required blade profile.

On the other hand, a stamped knife was cut or stamped from a metal sheet. And they are hammered into the required blade profile.

As a result, a forged kitchen knife is more robust, durable, and well-balanced than a stamped knife. A bolster is usually a good sign that you are working with a higher-end knife.

Although a traditional Japanese knife does not have a bolster. Some knife makers currently include them. And they were redesigning bolster designs to develop a fusion of a Japanese knife. And Western knife designs.

What are the different types of kitchen knife bolsters?

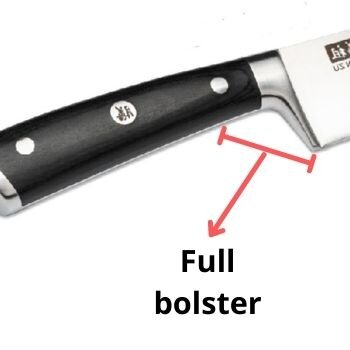

Full Bolster

On knives, with a full bolster, this piece can reach the bottom of the blade.

A finger guard structure on a larger full bolster may be used to avoid touch with the knife edge when using it.

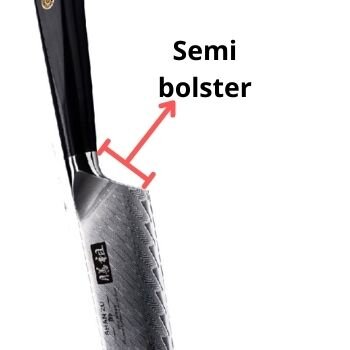

Semi Bolster

Some knives feature a semi-bolster designed to permit the knife edge to be fully used during chopping.

When comparing to sharpening a full bolster, a semi-bolster is also simpler to sharpen.

Which is better, a full bolster or semi bolster?

When filleting or boning fish, some cooks prefer a knife with a bolster. Others have just grown used to the bolster and like the knife’s form and grip.

It is worth mentioning that if you compare two German knives from the same knife maker. You will see that the full bolster and semi-bolster versions have distinct blade shapes. That results in a distinct cutting angle.

A semi-bolster or knife without a bolster has one remarkable characteristic. It will work well for cutting and other basic cooking tasks. Because you will be capable of using the total blade length for these tasks.

Furthermore, if you sharpen your knife often, a knife without a bolster will be way easier to sharpen.

However, when cleaning the sharp part near the tang. You will have to be a bit more cautious with your fingers and towels.

It is important to highlight that a full bolster enables you to exert a great deal of power on the blade with your hand. Without compromising your safety or the knife’s durability.

Although different knives are designed with a full bolster, a half bolster has many benefits. Notably, it enables a more powerful grasp, which we refer to as the pinch grip.

The pinch grip enables more accuracy while chopping. Since your hand is closer to the knife’s end rather than uncomfortably squeezing the handle.

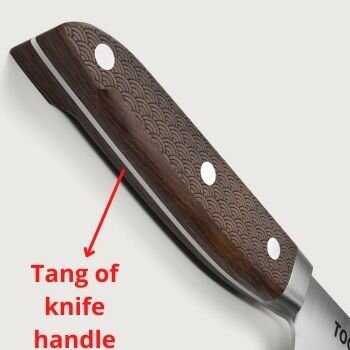

The Tang of the Kitchen Knife Handle

The tang is the portion of the kitchen knife that extends all the way through the handle and links the handle to the blade. It is occasionally fixed with rivets.

Tangs are classified into several distinct types, primarily based on their form.

What are the Two Common Types of Kitchen Knife Tangs?

Full and partial tang are the two most common forms of tang in kitchen knives.

Full Tang

One distinguishing aspect of a full tang handle is that it extends through the whole length and width of the handle.

It is worth noting that all expensive knives have a full tang handle as a standard feature. As a result, they are larger. And it can withstand more significant heavy-duty usage.

To sum it up, a full tang may provide superior leverage and balance. Which results in an excellent chopping experience.

Knives with full tangs, on the other hand, usually are more expensive. since they take more material to produce

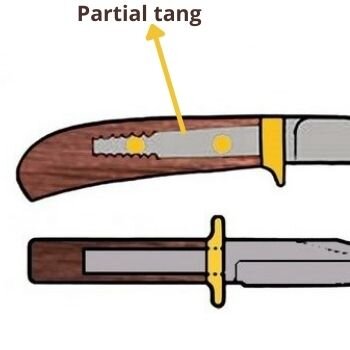

Partial Tang

A partial tang refers to a tang that does not reach the end of the kitchen knife handle.

There are many forms of partial tangs. Including the half tang, which runs half the length of the handle. The stick tang, which reaches until the end cap but is thin. And the narrowing tang, which narrows as it goes to the end cap.

Because partial tangs are smaller and need less material to make, they are often seen on cheap knives. Unfortunately, blades with these tangs are less likely to be long-lasting.

Unfortunately, where the tang and the blade connect, they often shatter. Also, after a few years of light use, the tang and handle often split apart.

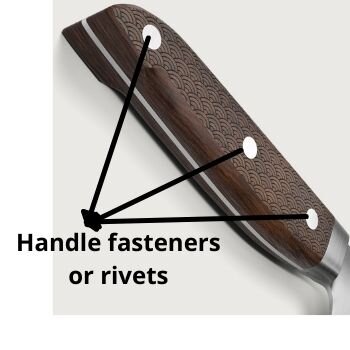

The Kitchen Knife Handle Fasteners

The tang is attached to the handle by the handle fasteners.

They might be rivets or screws. Rivets are often used since they are cheap and need minimal maintenance. But you have to replace the entire knife if a rivet got loose.

Screws, on the other hand, are adjustable and may be tightened. They may also be removed, allowing you to unscrew and clean your knife.

The disadvantage of screws is that you must frequently check them. Since they might get loose after using your kitchen knife for a long period.

Some extremely inexpensive knives lack handle fasteners. Instead, the tang and handles are super-glued together. Which will ultimately fall apart, leaving you with an unusable knife.